Our Services

Services

What distinguishes us apart is our ability to provide a full-service metal solution covering the whole metal fabrication process from R&D, prototyping, bending, cutting, stamping, welding, coating, polishing to the final installation stage of metal works.

Our state-of-the-art equipment and long-standing experience allow us to custom-make any size of metal components to the complete assemblies of components into functional systems, in accordance with our customer’s specifications. We are committed to working alongside with our customers as a one-stop metal solution and ensuring the most cost-effective outcome for them.

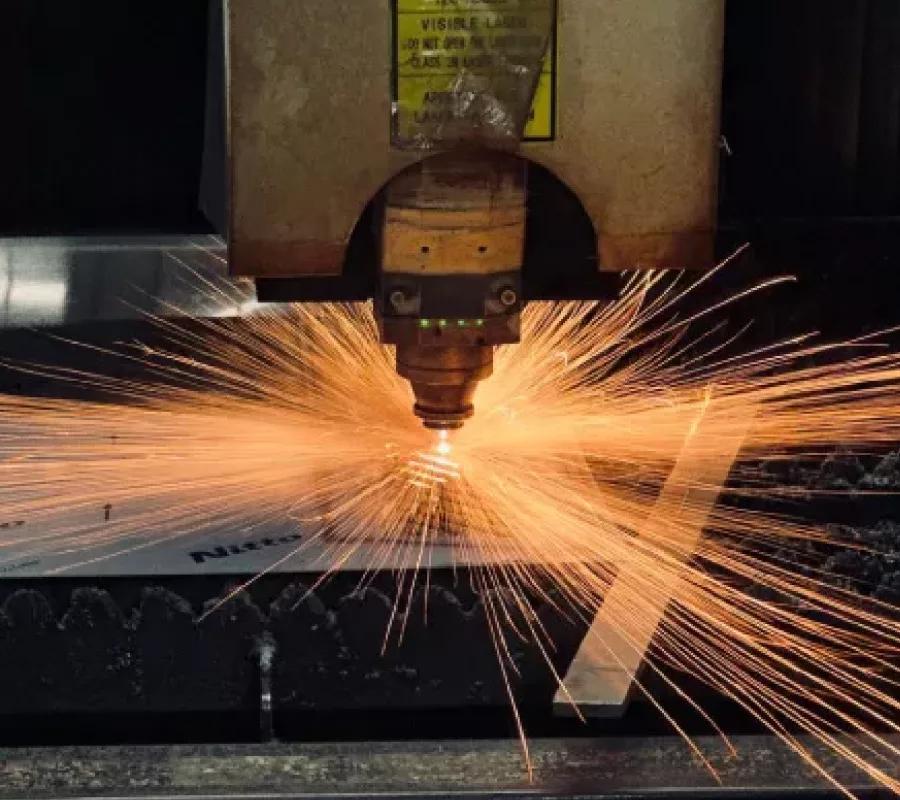

1. Laser Cutting

Laser cutting is a precision machining technique that uses a high-power laser beam to cut materials. By focusing the laser beam and directing it onto the material to be processed, laser cutting can achieve highly accurate cuts and complex shapes. It is widely used in the processing of various materials such as metal, plastic, wood, and glass, and is popular due to its high efficiency, high precision, and low pollution.

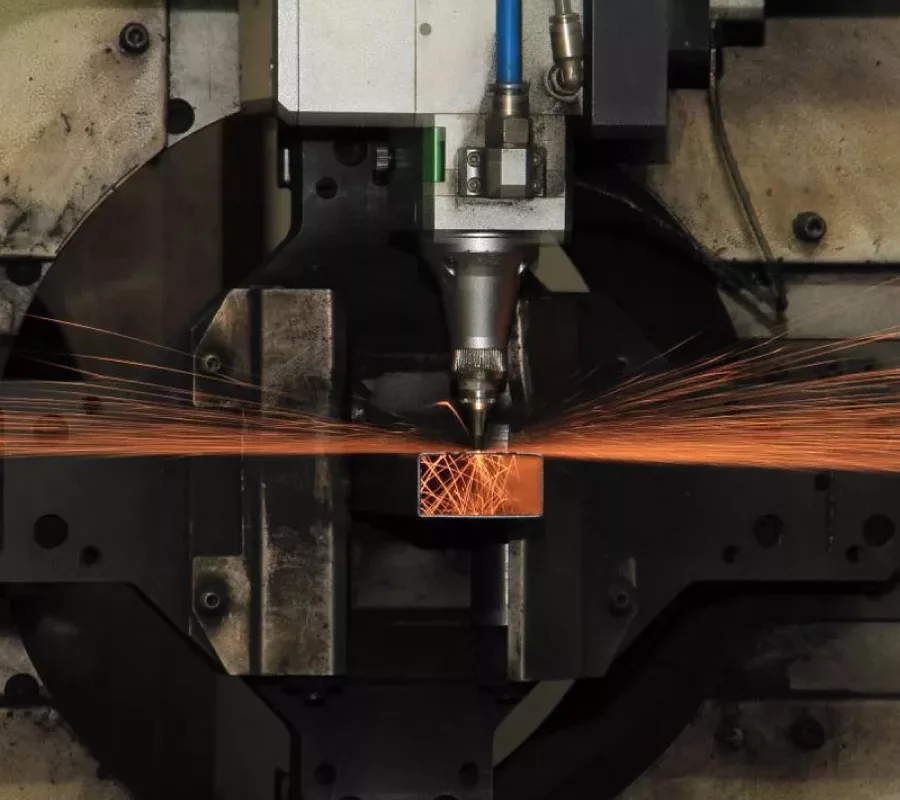

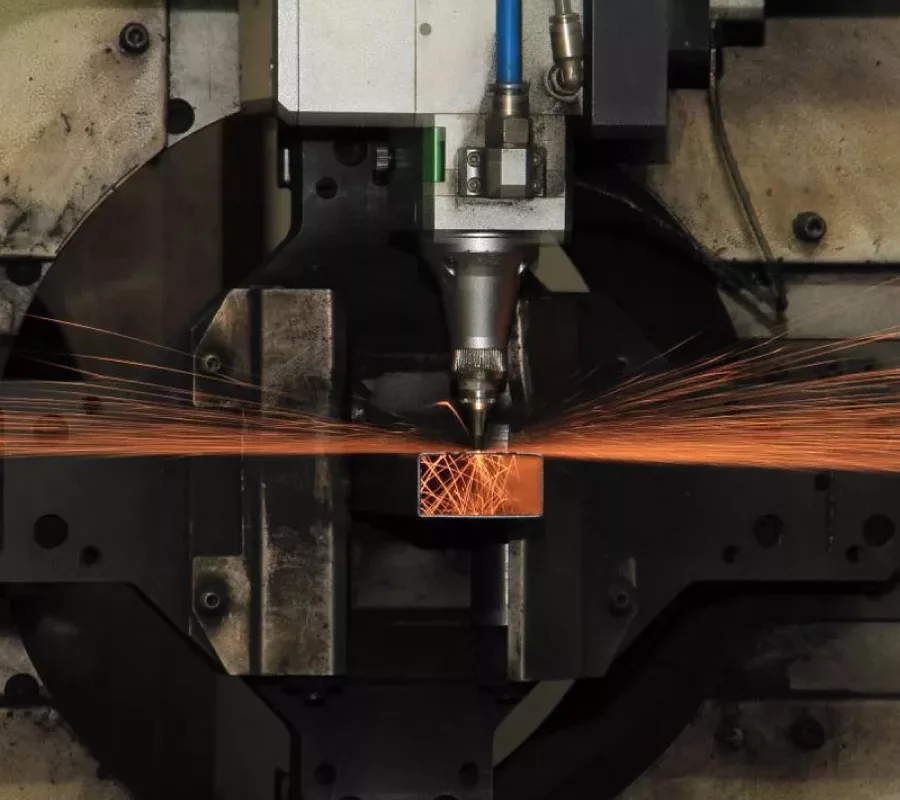

2. Laser Tube Cutting

Laser tube cutting is a process that uses laser technology to precisely cut tubular materials. By focusing a laser beam to melt and cut the tube, it achieves complex shapes and high precision. Laser tube cutting offers fast cutting speeds, high accuracy, and minimal heat-affected zones, making it widely used in metalworking, automotive manufacturing, and furniture production.

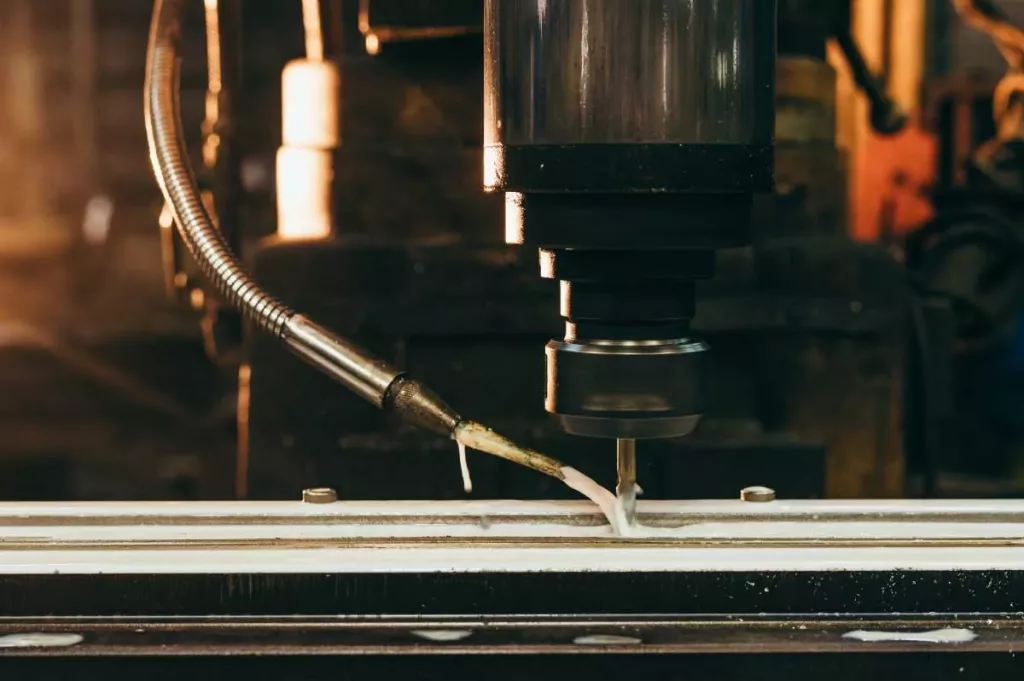

3.CNC Router

A CNC Router, or Computer Numerical Control Router, is an automated machining tool controlled by a computer. It can cut, carve, drill, and mill materials such as wood, metal, and plastic. A CNC Router typically consists of a machine tool, a control system, and CAD/CAM software. The operation process involves designing a graphic on a computer, then using the control system to convert the design into motion commands for the machine tool, thereby achieving precise material processing.

4. V-Cut Grooving

V-Cut Grooving is a machining technique that creates V-shaped grooves on the surface of a material, commonly used in the processing of printed circuit boards (PCBs) and various metal or non-metal plates. This technique uses specialized tools to cut V-shaped grooves in the material, making it easier to fold or separate the material.

5. Hydraulic CNC Pressbrake / Bending

A hydraulic CNC press brake is a machine used for bending sheet metal or plates. It utilizes hydraulic pressure to apply force on a workpiece, allowing it to be bent into various shapes and angles. The CNC (Computer Numerical Control) aspect means that the bending process is automated and controlled by a computer program, ensuring precise and consistent results. This technology is commonly employed in industries such as manufacturing, metalworking, and fabrication for its efficiency and accuracy.

6. CO2 MIG Welding

CO2 MIG welding, also known as gas metal arc welding (GMAW) with carbon dioxide (CO2) shielding gas, is a welding process where a continuous solid wire electrode is fed through a welding gun, along with a shielding gas, typically a mixture of CO2 and other gases. The electric arc formed between the wire and the workpiece melts the wire and the base metal, creating a weld pool that solidifies into a strong joint. CO2 MIG welding is commonly used in industries such as automotive, construction, and manufacturing for its efficiency, versatility, and relatively low cost.

7. Milling

Milling is a machining process that involves removing material from a workpiece using rotary cutters. These cutters have multiple cutting edges, which allow them to rapidly remove material from the workpiece. Milling machines can perform a wide range of operations, including cutting, drilling, and shaping, making them versatile tools in manufacturing and metalworking industries.

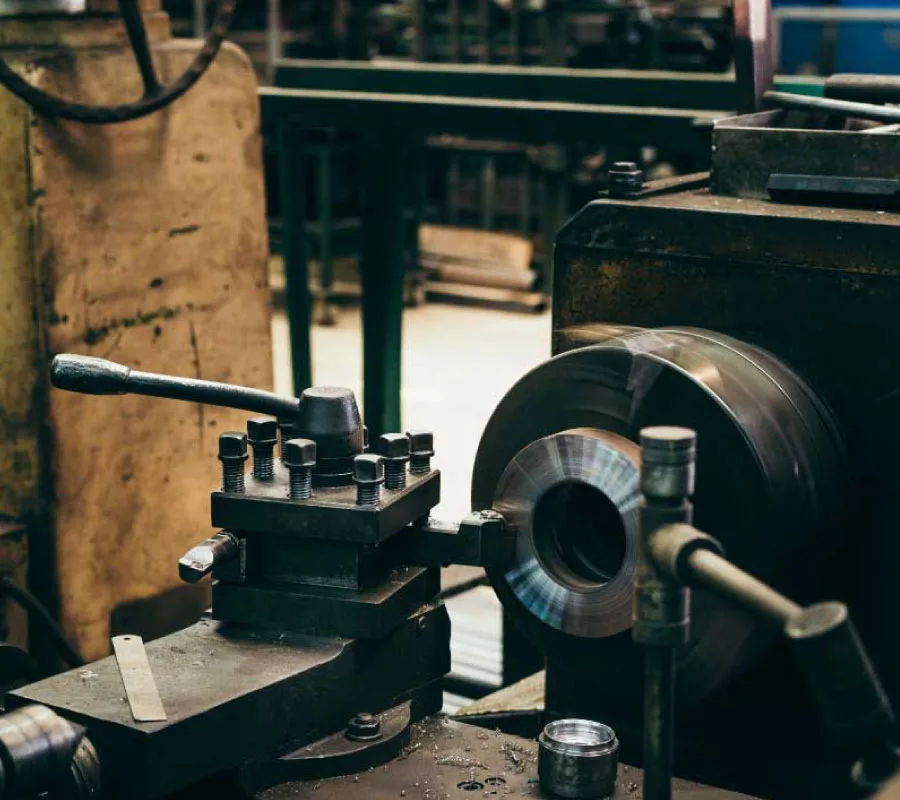

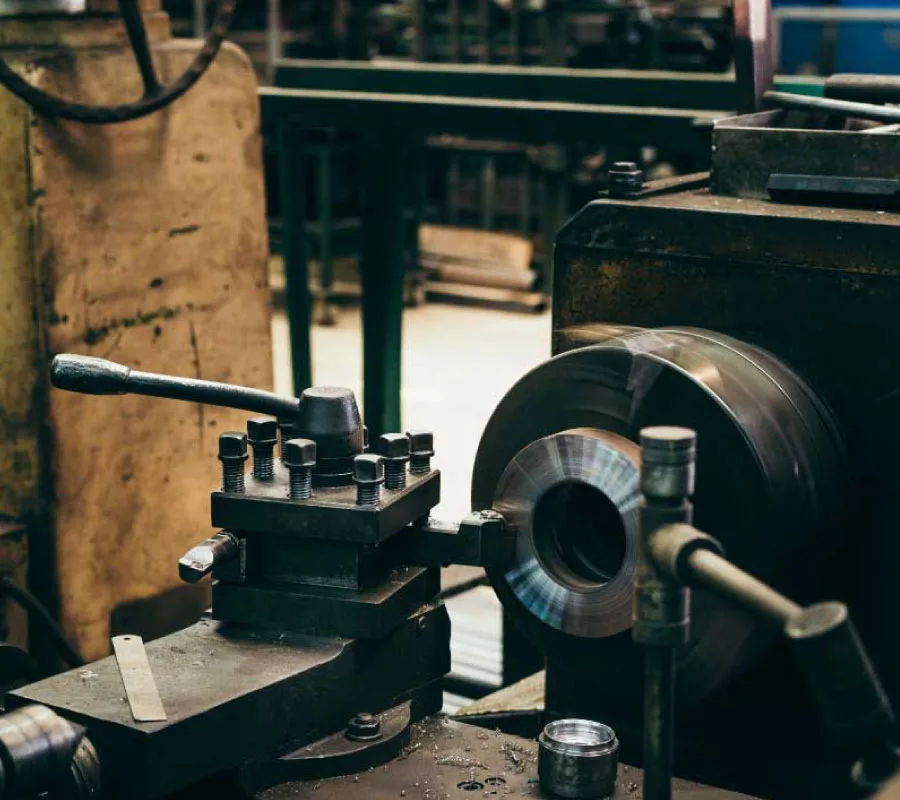

8. Lathe

A lathe is a machine tool used in metalworking and woodworking to rotate a workpiece about its axis. This rotation allows for precise cutting, sanding, drilling, or deformation of the material to create symmetrical objects such as cylinders, cones, and spheres. Lathes come in various sizes and configurations, from small benchtop models for hobbyists to large industrial machines for heavy-duty manufacturing.

9. Plate Rolling

Plate rolling is a metalworking process where flat sheets or plates of metal are gradually bent into curved shapes or cylinders. This process is typically performed using a plate rolling machine, which applies force to the metal as it passes through a series of rollers. Plate rolling is commonly used in industries such as manufacturing, construction, and shipbuilding to create cylindrical structures like pipes, tanks, and pressure vessels.

10. Hydraulic Profile & Pipe Bending

Hydraulic profile refers to the graphical representation of the water pressure and flow along a pipeline or channel. It shows how pressure and velocity change along the length of the pipe or channel, which is crucial for designing and analyzing hydraulic systems.

11. Laser Welding

Laser welding is a welding technique that uses a high-energy laser beam to melt and join materials. By focusing the laser beam, high temperatures can be generated in a very short time, causing the welding point to melt and cool quickly, forming a strong weld joint. Laser welding has the following advantages:

- High Precision: Laser welding can achieve micron-level precision control, making it ideal for welding precision parts.

- High Efficiency: Laser welding is fast, allowing welding operations to be completed in a short time.

- Low Thermal Impact: Due to the concentrated and high energy density of the laser beam, the heat-affected zone is small, helping to reduce material deformation and thermal damage.

12. Hairline Polishing

Hairline polishing is a surface treatment process used to create uniform fine lines on the surface of metals, giving them a matte finish and an aesthetically pleasing appearance. This process is commonly applied to materials such as stainless steel and aluminum, using tools like sandpaper, sanding belts, or polishing wheels to grind the metal surface. The purpose is to remove surface defects and improve visual appeal. Hairline polishing is widely used in home appliances, electronic products, automotive interiors, and architectural decoration.

13. Hydraulic Press

A hydraulic press is a machine that uses a hydraulic system to generate pressure for processing materials. By transferring pressure through a fluid (usually oil) within a closed system, a hydraulic press can apply immense force for pressing, shaping, bending, and shearing various materials. Hydraulic presses are widely used in manufacturing, especially in metalworking, automotive production, plastic molding, and powder metallurgy, due to their ability to provide stable and powerful pressure.

14. Power Press

A power press is a machine that uses mechanical pressure to shape or cut materials, typically used in metalworking. The power press applies pressure through an up-and-down moving ram to press the material into the desired shape or cut it to the required size. Power presses are widely used in industries such as automotive manufacturing, appliance production, aerospace, and construction, enabling efficient punching, stamping, bending, and shearing operations.

15. Robotic Welding

Robotic welding is a technology that uses robots to automate welding operations. Through programming and control, robots can perform welding tasks accurately, ensuring welding quality and consistency. Robotic welding is widely used in industries such as automotive manufacturing, shipbuilding, aerospace, and heavy machinery. It can increase production efficiency, reduce human errors, and enhance workplace safety.

16. Pipe Bending

Pipe bending refers to the process of shaping pipes or tubes by bending them to a desired angle or curvature. This technique is commonly used in various industries such as construction, plumbing, manufacturing, and automotive to create pipes that fit specific spatial requirements or to route pipes around obstacles efficiently.

Revillon Metal Sdn Bhd(0217812-T)

- 03-61568248 | 012-2250443

- Revillon@revillon.com.my

- Revillon Metal Sdn Bhd

- 2643, Jalan Baru Sungai Buloh, Kampung Baru Sungai Buloh, 40160 Shah Alam, Selangor